In today’s fast-evolving electronics industry, the quality and reliability of communication devices depend heavily on precision components. One critical element in the manufacturing process is the transceiver base mold, a core tool that shapes and supports transceiver modules in devices ranging from routers to 5G communication systems. Selecting the right mold is essential for achieving high efficiency, consistent quality, and cost-effective production. Aoke, a leading manufacturer in precision molds, offers a range of high-quality transceiver base molds designed to meet the rigorous demands of modern electronics production.

What Is a Transceiver Base Mold

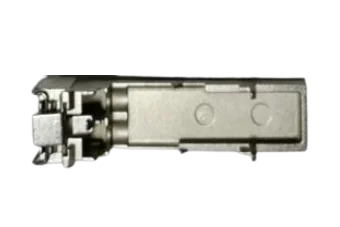

A transceiver base mold is a precision-engineered tool used to form, assemble, and support the base structure of transceiver modules. These molds ensure that each module maintains accurate alignment, mechanical stability, and dimensional consistency.

Unlike general-purpose molds, transceiver base molds are designed with tight tolerances and specific material considerations to accommodate the electrical and mechanical requirements of communication devices. Using a high-quality mold ensures that transceiver modules fit perfectly within housings, maintain thermal stability, and perform reliably throughout their lifecycle.

Why the Right Transceiver Base Mold Matters

1. Ensures Component Accuracy

The performance of a transceiver module depends on precise alignment of its internal components. Aoke’s transceiver base molds are engineered with micron-level precision, ensuring every module produced has exact dimensions and alignment. This reduces assembly errors and improves device reliability.

2. Enhances Production Efficiency

A poorly designed mold can lead to frequent adjustments, production delays, and higher scrap rates. High-quality molds from Aoke streamline the production process by enabling smooth material flow, quick cycle times, and minimal downtime, increasing overall manufacturing efficiency.

3. Reduces Defective Rates

Variability in mold quality can result in defects such as warping, misalignment, or incomplete formation. Aoke’s transceiver base molds use advanced materials and precision machining to maintain consistent performance, significantly lowering defective rates and saving costs.

4. Supports Advanced Materials

Modern communication devices often incorporate specialized plastics, composites, or high-performance polymers. Aoke designs transceiver base molds to handle these materials efficiently, ensuring proper molding without deformation or stress cracks.

5. Extends Mold Lifespan

Durability is a key consideration. Aoke employs high-grade steel and surface treatments to ensure long-term mold performance, reducing the need for frequent replacements and minimizing production interruptions.

Key Features of Aoke’s Transceiver Base Molds

Precision Engineering: Tight tolerances for consistent module performance.

Durable Materials: High-grade steels and coatings for long-lasting use.

Optimized Design: Ensures proper heat dissipation, material flow, and alignment.

Customization Options: Tailored molds for specific transceiver designs and production scales.

Compatibility: Suitable for various assembly methods, including automated production lines.

By combining these features, Aoke provides molds that not only improve product quality but also enhance operational efficiency and cost-effectiveness.

Applications Across the Electronics Industry

The transceiver base mold is widely used in the manufacturing of:

Wireless Communication Devices: Routers, modems, and 5G transceiver modules.

Optical Communication Systems: Fiber optic transceivers requiring precise alignment.

IoT Devices: Small-form-factor transceivers for sensors and smart devices.

Telecommunication Equipment: High-volume modules for enterprise networks.

Industrial Communication Devices: Reliable modules for harsh environments.

In each application, Aoke’s transceiver base molds help ensure that components meet stringent performance standards, providing a foundation for reliable and high-speed communication.

Why Choose Aoke for Your Transceiver Base Mold Needs

With extensive experience in precision mold manufacturing, Aoke combines advanced engineering, material expertise, and rigorous quality control. Key advantages of partnering with Aoke include:

Technical Expertise: Years of experience in producing molds for high-performance electronic components.

Customization: Ability to design molds tailored to your specific product requirements.

Quality Assurance: Strict inspection and testing procedures to ensure consistent performance.

Global Support: Comprehensive after-sales service, maintenance guidance, and technical consultation.

By choosing Aoke, manufacturers gain a reliable partner capable of supporting high-volume production while maintaining exceptional quality standards.

Tips for Selecting the Right Transceiver Base Mold

Assess Material Compatibility: Ensure the mold is suitable for your selected polymer or composite.

Consider Production Volume: Choose molds that match your cycle-time requirements for efficiency.

Check Precision Standards: Opt for molds with micron-level tolerances for critical alignment.

Evaluate Durability: High-grade steel and surface treatment extend mold life.

Select a Trusted Manufacturer: Work with companies like Aoke that offer quality assurance and technical support.

Conclusion

In the competitive electronics industry, the right transceiver base mold can make the difference between a reliable product and costly production errors. Aoke delivers high-precision, durable, and customizable molds designed to meet the exacting requirements of modern communication devices. By investing in quality molds from Aoke, manufacturers can enhance production efficiency, reduce defects, and ensure consistent product performance — establishing a strong foundation for success in the electronics market.